A Plastic Model of Steel

| Item Number | tk000100 |

| Item Name | FLAT PACKING CHAIR |

| Price | 59,850 yen |

| Limited | No |

| Size | Before assembly : |

| Material | Steel |

| Payment Methods | PayPal |

| Shipping | Shipping costs will be emailed after order (all items ship from Japan) |

| Time to delivery | Two weeks |

| Notes | Returns are not accepted. |

| Buyer | Yanagisawa |

A Plastic Model of Steel

Simply put, that's it. Out of a piece of steel the size of one tatami mat, two chairs of different sizes are born. Cut out, bend, assemble, done!

However, this explanation does no justice to how fun it actually is!

I was most attracted by the systematic beauty of a sheet of metal which could be taken apart, then put together like a huge plastic model. I'm sure a certain type of person reading this has already been sucked in by this description alone.

I really came to understand the beauty of this creation when I tried going through the pain of putting it together. What a mistake! It had me hook, line and sinker.

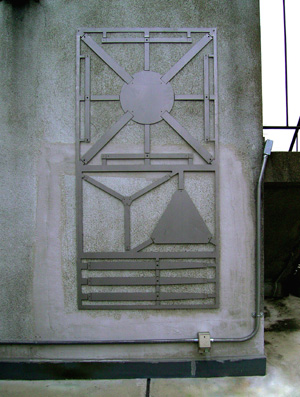

Put it on the wall! Put it together! An arousing size. An arousing shape.

After easy construction, two stools are finished.

As you cut and bend your hands will be surprised by a new experience.

From here, it looks like your average plastic model.

![]()

Adult fun

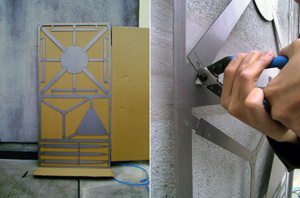

A box with a sheet of metal arrives, and we are ready to begin. My strongest impression is from when I first saw the steel plate. I started to tremble with excitement. There is something exciting about steel itself. It has a dull glow, yet also seems supple. I was surprised to fall for its appearance as I did. From here on, its cooking time!

I have several kits for putting furniture together, but work on this steel plate begins by taking the pieces out. This process of removing pieces most resembles working with plastic models. It's also a bit different than having parts shipped to you from your average mail-order furniture retailer.

There are no special techniques required, and the instructions look fairly simple, yet just the right amount of trial and error is necessary to be successful. That difficulty is probably in the distance between myself and the steel. I've never had the opportunity to hold my own against steel. So at first things didn't go as I'd expected.

As a result, I'd like to make it clear: make the stool you like more last. The second time around you've learned the ins and outs of working with the steel, so expect improvements in your construction.

We started thinking, "Let's just make it!", and in the end it turned into an outdoor event with five people working on the roof. Once we learned how important getting used to the material and building our intuition was, we wanted to more stools to further test our skills. If we had unlimited space we would've loved to keep on constructing.

So what happened to the leftover steel? As I tried to make it more compact by bending it, I fell in love with its weight and strength, so I ended up keeping it as a piece of art, a reminder. There were unexpected uses in this wreckage!

I hope you are imaging several work environment possibilities!

For example, include your friends, work under the sun on a pleasant day, make use of a holiday - utilize the wisdom and strength of others. Of course, you could build it alone, inside, but I think it's more fun in a group! When you're finished the feeling of completion, the sweat of satisfaction will be enhanced by everyone's presence.

Of course you can use the stool you finish, and paint it to your liking. There'll be stories which continue after you finished assembly. Don't worry about being sensitive with the stool, throw it around and take advantage of the material.

I've talked about assembly so far, but let me mention something else important. It's different than your average plastic model. It's also different from your average do-it-yourself furniture. Even if you're not interested in steel or assembly, the steel plate alone is a piece of art.

It looks great if you display it as is. I wouldn't be surprised if all some people want to do is put it on display. There are screw holes around the corners, so you can easily attach it to the wall or in front of a window.

You'll never loose the chance of construction, so maybe it's best to let it sit as is, enjoy the view for awhile before getting your hands dirty. As adults, we were looking forward to such a fun opportunity!

> Click here for assembly instructions (PDF)

Fresh out of the box. You start by cutting it out.

Depend on your instincts as you bend and fold. 5 of us are engrossed.

Nippers, screw driver, file - that's all you need.

No waste, it's a piece of art. Color can also be applied.

![]()

It's not over yet

What mind is behind this fun?

Architect Ashizawa Keiji.

He's sociable and charming.

As his parched laugh fills the room he brings out a sketch book and starts putting ideas together. Soon enough he's reached a working example.

He led the assembly of our chairs, and his footwork was amazing.

I look forward to introducing a new piece in the FLAT PACKING series.

Have high expectations!

For more about Mr. Ashizawa's work:

> Keiji Ashizawa Design Office

The creator constructing his creation, with a smile of success.